At Gemba Solutions, we’re committed to helping organisations achieve operational excellence through lean principles and continuous improvement. We’re excited to introduce our latest offering – a comprehensive 5S training course designed to transform your workplace into a haven of efficiency and productivity. In this blog, we’ll explore the significance of 5S, what our training course entails, and the benefits.

What is 5S?

Before delving into the details of our new training course, let’s briefly discuss what 5S is and why it’s an essential component of lean manufacturing and operational excellence.

5S is a methodology rooted in Japanese manufacturing practices, and its name derives from five key principles:

- Sort: The first step involves sorting and removing unnecessary items from the workplace. This decluttering process not only creates more space but also reduces the time spent searching for tools or materials.

- Set in order: Once you’ve sorted out the essential items, it’s time to organise them systematically. This means designating specific locations for tools, equipment, and materials to ensure easy access and visual management.

- Shine: Maintaining a clean and organised workspace is crucial for efficiency and safety. Regular cleaning and inspections help identify and address issues before they escalate.

- Standardise: To sustain the improvements made through sorting, setting in order, and shining, it’s essential to establish standardised processes and procedures. This consistency ensures that everyone in the organisation follows the same best practices.

- Sustain: The final ‘S’ in 5S involves creating a culture of continuous improvement. Team members are encouraged to adhere to the established standards and identify opportunities for further enhancements.

Our New 5S Training Course

Now that we’ve covered the basics of 5S let’s explore what our new training course has to offer.

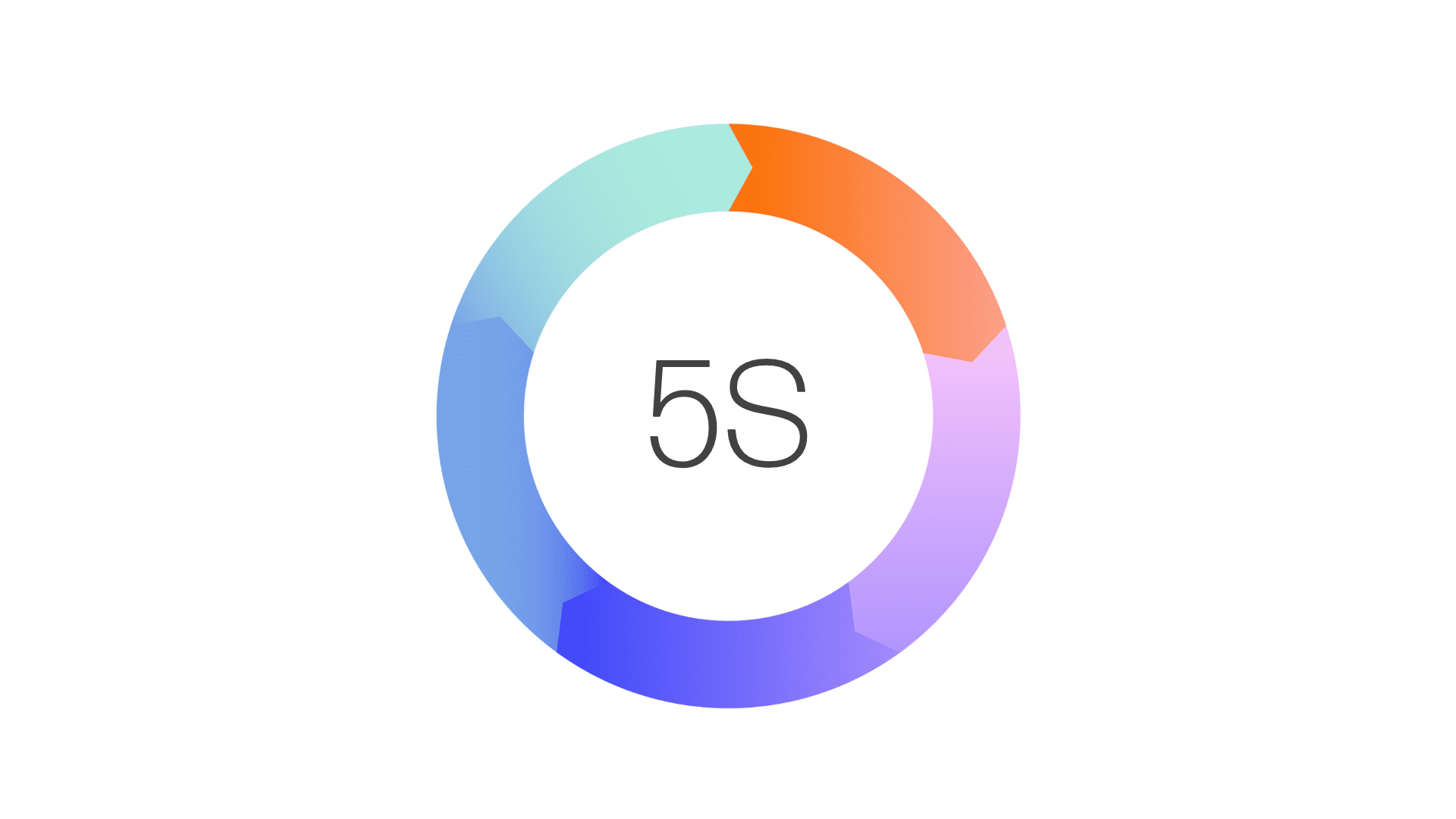

Comprehensive Curriculum: Our 5S training course is meticulously designed to provide you with a deep understanding of the 5S methodology. You’ll learn the principles, techniques, and tools required to successfully implement 5S in your workplace.

Practical Workshops: We believe in learning by doing. Our course includes hands-on workshops, where you’ll have the opportunity to apply 5S principles in a real-world setting. This practical experience will empower you to implement 5S effectively in your organisation.

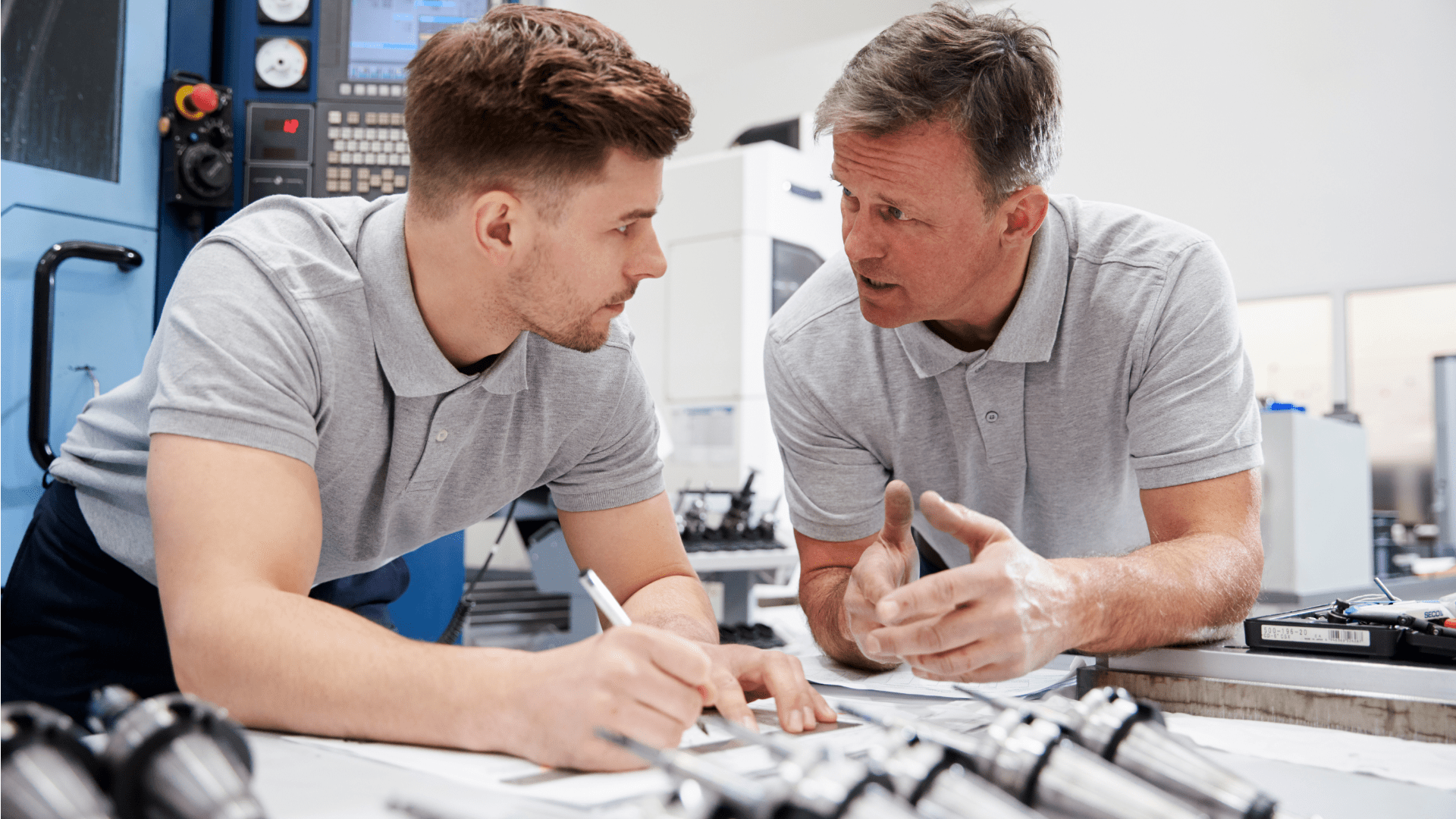

Expert Instructors: Our instructors are seasoned experts with years of experience in lean manufacturing and 5S implementation. They will guide you through the course, provide valuable insights, and answer any questions you may have.

Benefits of 5S Training

By enrolling in our 5S training course, you can expect to enjoy a wide range of benefits:

- Increased Efficiency: 5S streamlines processes and reduces waste, leading to increased efficiency and productivity.

- Enhanced Safety: A clean and organised workplace reduces the risk of accidents and injuries.

- Improved Morale: A well-organised workspace promotes a sense of pride and ownership among employees.

- Cost Savings: 5S helps eliminate unnecessary spending on excess inventory and wasted time.

- Sustainable Improvements: With our 5S training, you’ll be equipped to maintain and build upon the improvements made through 5S.

At Gemba Solutions, we’re excited to offer our new 5S training course to organisations looking to enhance their operational excellence. With our comprehensive curriculum, practical workshops, and expert instructors, you’ll be well-prepared to implement 5S and reap the benefits of a more efficient and organised workplace. Take the first step towards a leaner, more productive future.

Contact us today to learn more and get started on your journey to operational excellence!

FAQs

Is 5S training a good framework?

5S is a great framework because it emphasises the use of a specific mindset and tools to create efficiency and value. The 5S checklist guides manufacturers in observing, analysing, collaborating, and searching for waste and also involves the practice of removing waste.

What is the purpose of 5S?

The purpose of 5S is to make a workplace function better by making it an easier place to work. This occurs by making spaces make sense; tools and materials are placed in logical locations based on who needs them, how frequently they’re needed, etc. Spaces are cleaned regularly. Cleaning and organisation become habits. When used correctly, 5S ultimately makes processes safer and more efficient.

What is the best way to implement 5S lean manufacturing?

- Educating employees

- Providing examples and a framework for success

- Providing insight about how the 5S process will actually operate to help alleviate some of the unknowns that could hinder the process

- Relying on Gemba to provide effective 5S training for you and your team to properly implement